Batch Treatment Systems Model SQBR Sequencing Batch Reactor

Applied Mechanical Technology is an industry leader in industrial wastewater treatment components and systems. Since 1997 we’ve been designing and building industrial equipment and systems for variety of industries.

We design and build all our core technology equipment in-house. Our complete line of equipment includes:

- Oil Water Separators,

- DAF Dissolved Air Flotation,

- Inclined plate Clarifiers,

- Multimedia filters

- Controls Packages.

These are the core of our complete systems packages. We complete our systems with strategic OEM relationships for all the other necessary components such as instruments, pumps, valves etc.

As we design and manufacture our core equipment and systems in our own shop we have the flexibility and the ability to configure our systems as needed to meet the most stringent project specifications while exceeding customer’s expectations.

Principal of Operation – SQBR Sequencing Batch Reactors

The SQBR Sequencing Batch Reactors are perfect for small (<100,000 GPD) difficult wastewater streams. With small daily wastewater flows it is often more economical to treat in a batch system instead of employing a larger continuous flow thu system.

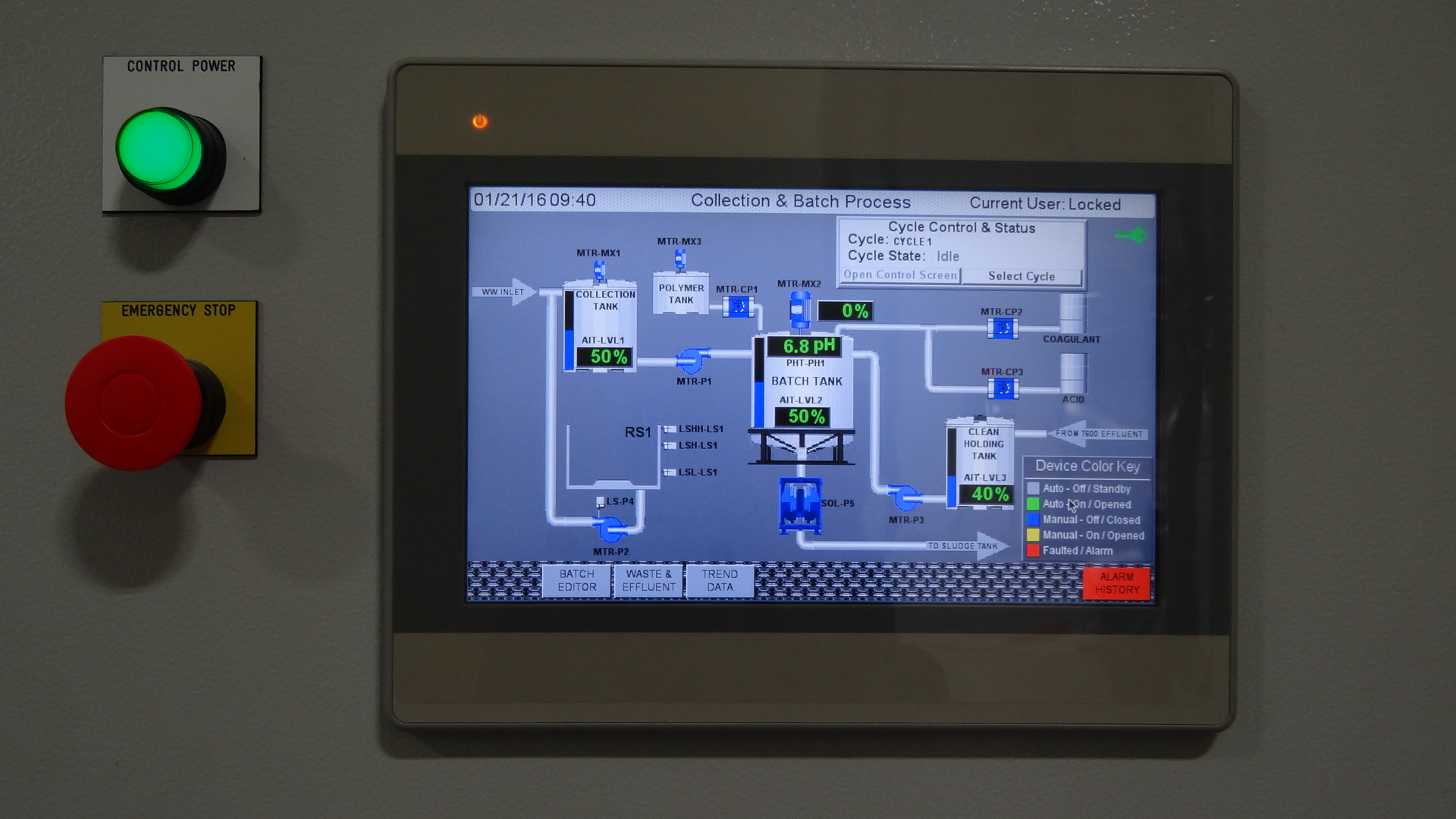

Sequencing Batch operation involves a programmable control system that will sequence the chemical treatment steps as operator programmed to achieve the chemical treatability regime. The Applied Mechanical Technology SQBR system is full operator programmable in steps and tasks and several “recipes” can be developed and saved for future use. The SQBR recipes are scaled up version of treatability bench testing. The operator can either enter actual treatability results (ml of chemical in a 500 ml beaker) or direct ppm dosing rates (example; metal precipitators). The control system does the rest and determines dosing pump runtime duration.

Typical treatment sequencing batch reaction steps include, but are not limited to:

- Initial mixing, to get the contents homogenized. Rapid mixing for 3-5 minutes.

- pH adjustment while mixing, either acidification or caustic mixing. Rapid mixing for 10-15 minutes.

- Reduction for Cr6 reduction to Cr3. Rapid mixing, ORP monitoring, reductant addition for 20-40 minutes.

- Specialty metal precipitator step. Rapid mixing for 5-15 minutes.

- Coagulant mixing step. Rapid mixing for 10-15 minutes.

- Flocculent step. Slow gentle mixing for 3-5 minutes.

Our SQBR Sequencing Batch Reaction systems are found in a variety of industries including but not limited to:

- Heavy machinery repair. Parts washing cabinet wastewater.

- Small metal stamping facilities

- Small machine shops

- Flexographic ink printers, cartons, cardboard, etc.

Typical Options Include:

- HDPE, Mild steel or stainless steel construction

- Special coatings internal and/or external

- XP rated explosion proof or intrinsically safe electrical components

- Top surface oil/scum skimmers

- Complete control packages

- Pump skids, inlet, effluent, oil, sludge

- Operator platforms

- Effluent filters

Need a Quote?

Click here for our Application Questionnaire to obtain a quote.

Quality

We use only the highest quality materials, pumps, instruments, valves and controls components to ensure you the heavy duty robust performance you demand in today’s highly competitive market environment. All our systems are built to the highest standards of craftsmanship and are extensively tested throughout the fabrication process. We perform a variety of NDE testing including PQR, UT, XT, full hydro, dye penetrant, ASME pressure testing and of course visual inspections and functional testing both in-shop and in the field.

Controls

Our operator controls interface scheme is the most advanced in the wastewater industry. We offer basic simplified controls to full featured controls systems that use SQL database platforms permitting the generation, archiving and managed all trending and effluent data. Our most advanced controls offer operator input of bench treatability testing that then allow the system .We design and build all our own controls in-house to UL-508A Industrial Control Panel standards with strict conformance to NEC, ANSI and NFPA regulations. All panels are built to UL standards and are individually UL certified if required.

Tankwash Systems

Our Industrial Tankwash Division designs and builds Railcar and Tank Trailer Internal wash systems to wash everything from Crude oil to Edible oils, from Chemicals to Corn Starch and everything in between. When you wash an industrial tank, you create an industrial wastewater and we take care of that too.